Air Bearing Spindle Repair

Air Bearing Spindle Repair

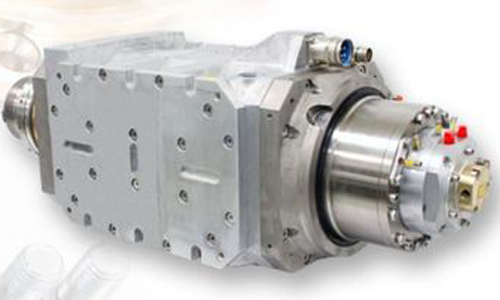

HST repairs damaged dicing spindles and back grinding spindles. HST was started in 1986 to support wafer dicing companies throughout the world and provide rapid, OEM quality repairs on all types of dicing and back grinding spindles.

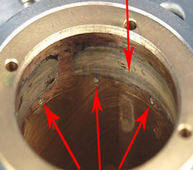

If the air bearing spindle on your dicing saw is damaged in any way, we can restore it to like new condition. We specialize in repairing broken tips and damage caused by “crashes”.

HST has highly trained technicians who know all of the nuances of dicing and back grinding spindles. After repair every spindle is run at full speed and perfectly balanced. We guarantee that the TIR will be less than 1 µm. Every spindle is load tested and pressure tested. All spindles must perform up to OEM specification before we will ship it.