สาเหตุการเสียหายของตลับลูกปืน

เมื่อตลับลูกปืนเกิดการชำรุดเสียหายในระหว่างการทำงาน เครื่องจักรหรืออุปกรณ์นั้นๆอาจเกิดการชำรุด เสียหาย และหยุดกะทันหัน หรือ ทำงานได้ไม่เป็นปกติเหมือนเดิม ไม่ว่าตลับลูกปืนจะเสียหายในรูปแบบไหน ทั้งหมดล้วนเป็นสิ่งที่ก่อให้เกิดปัญหา ดังนั้นสิ่งที่สำคัญคือต้องสามารถที่จะแยกแยะหรือคาดการณ์สถานการณ์เหล่านี้ล่วงหน้าได้ เพื่อให้สามารถเกิดการป้องกันไว้ได้ก่อน

หนังสือเล่มนี้อธิบายถึงการวิธีการจัดการตลับลูกปืน การติดตั้ง การหล่อลื่น และการบำรุงรักษาที่ถูกต้อง เพื่อป้องกันการเสียหายของตลับลูกปืนก่อนเวลา พร้อมกับภาพถ่ายสีของของตลับลูกปืนที่เสียหายในลักษณะต่างๆกัน การเสียหายก่อนเวลาของตลับลูกปืนส่วนใหญ่สามารถหลีกเลี่ยงได้ สาเหตุหลักๆของการเสียเกิดจาก การติดตั้งที่ไม่ถูกต้อง การจัดการที่ไม่เหมาะสม การหล่อลื่นที่ไม่ดี การปนเปื้อนของสิ่งแปลกปลอม และอุณหภูมิการทำงานที่ร้อนผิดปกติ เป็นต้น

ถ้าเราสามารถหาข้อมูลทั้งหมดทั้งก่อนและหลังการเสียหาย รวมถึงลักษณะและสภาพของการใช้งาน สภาพสิ่งแวดล้อม เราก็อาจหาแนวทางแก้ไขปัญหาไม่ให้เกิดขึ้นซ้ำขึ้นได้อีกในอนาคต โดยศึกษาลักษณะของความเสียหายและสาเหตุที่เป็นไปได้

In general, if rolling bearings are used correctly, they will survive to their predicted fatigue life. Bearings, however, often fail prematurely due to avoidable mistakes. In contrast to fatigue life, this premature failure is caused by improper mounting, mishandling, poor lubrication, entry of foreign matter or abnormal heat generation.

If all conditions are known for the times both before and after the failure, including the application, the

operating conditions, and environment, then a measure can be determined by studying the nature of the failure and its probable causes. A successful measure will reduce similar failures or prevent them from happening again.

Bearing Damage and Countermeasures: Flaking

Damage Cond

Flaking occurs when small pieces of bearing material are split off from the smooth surface of the raceway or rolling elements due to rolling fatigue, thereby creating regions having rough and coarse texture.

Possible Cause

- Excessive load

- Poor mounting (misalignment)

- Moment load

- Entry of foreign debris, water penetration

- Poor lubrication, Improper lubricant

- Unsuitable bearing clearance

- Improper precision for shaft or housing, unevenness in housing rigidity, large shaft bending

- Progression from rust, corrosion pits, smearing,dents (Brinelling)

Countermeasure

- Reconfirm the bearing application and check the load conditions

- Improve the mounting method

- Improve the sealing mechanism, prevent rusting during non-running

- Use a lubricant with a proper viscosity, improve the lubrication method

- Check the precision of shaft and housing

- Check the bearing internal clearance

Part: Inner ring of an angular contact ball bearing

Symptom: Flaking occurs around half of the circumference of the raceway surface

Cause: Poor lubrication due to entry of cutting coolant into bearing

Part: Inner ring of an angular contact ball bearing

Symptom: Flaking occurs diagonally along raceway

Cause: Poor alignment between shaft and housing during mounting

Bearing Damage and Countermeasures: Flaking

Part: Balls

Symptom: Flaking of ball surface

Cause: Dents due to shock load while stationary

Part: Outer ring

Symptom: Flaking of raceway surface at ball pitch

Cause: Dents due to shock load while stationary

Part: Rollers of a cylindrical roller bearing

Symptom: Premature flaking occurs axially on the rolling surfaces

Cause: Scratches caused during improper mounting

Bearing Damage and Countermeasures: Flaking

Damage Condition

Flaking occurs when small pieces of bearing material are split off from the smooth surface of the raceway or rolling elements due to rolling fatigue, thereby creating regions having rough and coarse texture.

Possible Cause

- Excessive load

- Poor mounting (misalignment)

- Moment load

- Entry of foreign debris, water penetration

- Poor lubrication, Improper lubricant

- Unsuitable bearing clearance

- Improper precision for shaft or housing, unevenness

in housing rigidity, large shaft bending - Progression from rust, corrosion pits, smearing,

dents (Brinelling)

Countermeasure

- Reconfirm the bearing application and check the load conditions

- Improve the mounting method

- Improve the sealing mechanism, prevent rusting during non-running

- Use a lubricant with a proper viscosity, improve the lubrication method

- Check the precision of shaft and housing

- Check the bearing internal clearance

Part: Inner ring of a spherical roller bearing

Symptom: Round shaped peeling pattern occurs on the

center of the raceway surface

Cause: Poor lubrication

Bearing Damage and Countermeasures: Peeling

Part: Convex rollers

Symptom: Round shaped peeling pattern occurs on the center of the rolling surfaces

Cause: Poor lubrication

Part: Outer ring of a spherical roller bearing

Symptom: Peeling occurs near the shoulder of the raceway over the entire circumference

Cause: Poor lubrication

Bearing Damage and Countermeasures: Scoring

Damage Condition

Scoring is surface damage due to accumulated small seizures caused by sliding under improper lubrication or under severe operating conditions. Linear damage appears circumferentially on the raceway surface and rolling surface. Cycloidal shaped damage on the roller end. Scoring on rib surface contacting roller end.

Possible Cause

- Excessive load, excessive preload

- Poor lubrication

- Particles are caught in the surface

- Inclination of inner and outer rings

- Shaft bending

- Poor precision of the shaft and housing

Countermeasure

- Check the size of the load

- Adjust the preload

- Improve the lubricant and the lubrication method

- Check the precision of the shaft and housing

Part: Inner ring of a spherical roller bearing

Symptom: Scoring on large rib face of inner ring

Cause: Roller slipping due to sudden acceleration and deceleration

Part: Convex rollers

Symptom: Scoring on roller end face

Cause: Roller slipping due to sudden acceleration and deceleration

Part: Cage of a deep groove ball bearing

Symptom: Scoring on the pressed-steel cage pockets

Cause: Entry of debris

Part: Convex rollers of Photo 3.5

Symptom: Scoring on the roller end face

Cause: Debris, which is caught in surface, and excessive axial loading

Bearing Damage and Countermeasures: Scoring

Damage Condition

Scoring is surface damage due to accumulated small seizures caused by sliding under improper lubrication or under severe operating conditions. Linear damage appears circumferentially on the raceway surface and rolling surface. Cycloidal shaped damage on the roller end. Scoring on rib surface contacting roller end.

Possible Cause

- Excessive load, excessive preload

- Poor lubrication

- Particles are caught in the surface

- Inclination of inner and outer rings

- Shaft bending

- Poor precision of the shaft and housing

Countermeasure

- Check the size of the load

- Adjust the preload

- Improve the lubricant and the lubrication method

- Check the precision of the shaft and housing

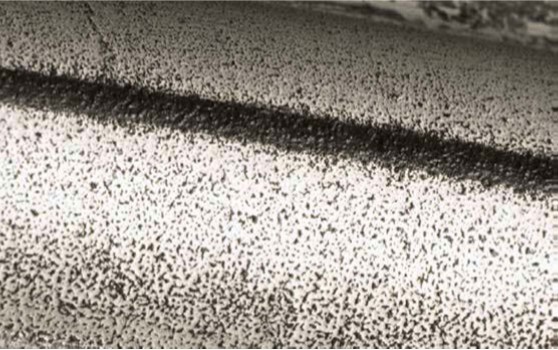

Part: Outer ring

Symptom: Smearing occurs circumferentially on raceway surface

Cause: Roller slipping due to excessive grease filling

Part: Convex rollers

Symptom: Smearing occurs at the center of the rolling surface

Cause: Poor lubrication

Bearing Damage and Countermeasures: Cracks

Damage Condition

Cracks in the raceway ring and rolling elements. Continued use under this condition leads to larger cracks or fractures.

Possible Cause

- Excessive interference

- Excessive load, shock load

- Progression of flaking

- Heat generation and fretting caused by contact between mounting parts and raceway ring

- Heat generation due to creep

- Poor taper angle of tapered shaft

- Poor cylindricality of shaft

- Interference with bearing chamfer due to a large shaft corner radius

Countermeasure

- Correct the interference

- Check the load conditions

- Improve the mounting method

- Use an appropriate shaft shape

Part: Outer ring of a double-row cylindrical roller bearing

Symptom: Thermal cracks occur on the outer ring side face

Cause: Abnormal heat generation due to contact sliding

between mating part and face of outer ring

Part: Roller of a tapered roller thrust bearing

Symptom: Thermal cracks occur at large end face of roller

Cause: Heat generation due to sliding with the inner ring rib

under poor lubrication

Bearing Damage and Countermeasures: Pitting

Damage Condition

The pitted surface has a dull luster which appears on the rolling element surface or raceway surface.

Possible Cause

- Debris becomes caught in the lubricant

- Exposure to moisture in the atmosphere

- Poor lubrication

Countermeasure

- Improve the sealing mechanism

- Filter the lubrication oil thoroughly

- Use a proper lubricant

› Improve the sealing mechanism

› Filter the lubrication oil thoroughly

› Use a proper lubricant

Part: Ball

Symptom: Pitting occurs on the rolling element surface

Bearing Damage and Countermeasures: Wear

Damage Condition

Possible Cause

- Entry of debris

- Progression from rust and electrical corrosion

- Poor lubrication

- Sliding due to irregular motion of rolling elements

Countermeasure

- Improve the sealing mechanism

- Clean the housing

- Filter the lubrication oil thoroughly

- Check the lubricant and lubrication method

- Prevent misalignment

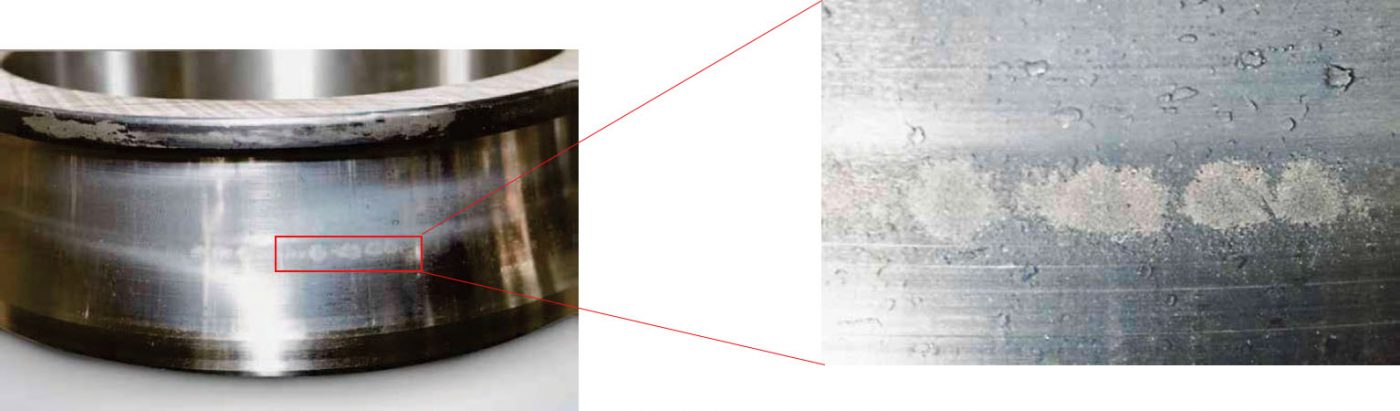

Part: Outer ring of a spherical roller bearing

Symptom: Wear having a wavy or concave-and-convex texture on loaded

side of raceway surface

Cause: Entry of debris under repeated vibration while stationary

Part: Tapered rollers of Photo 10.3

Symptom: Stepped wear on the roller head and face

Cause: Fretting progression due to excessive load while stationary

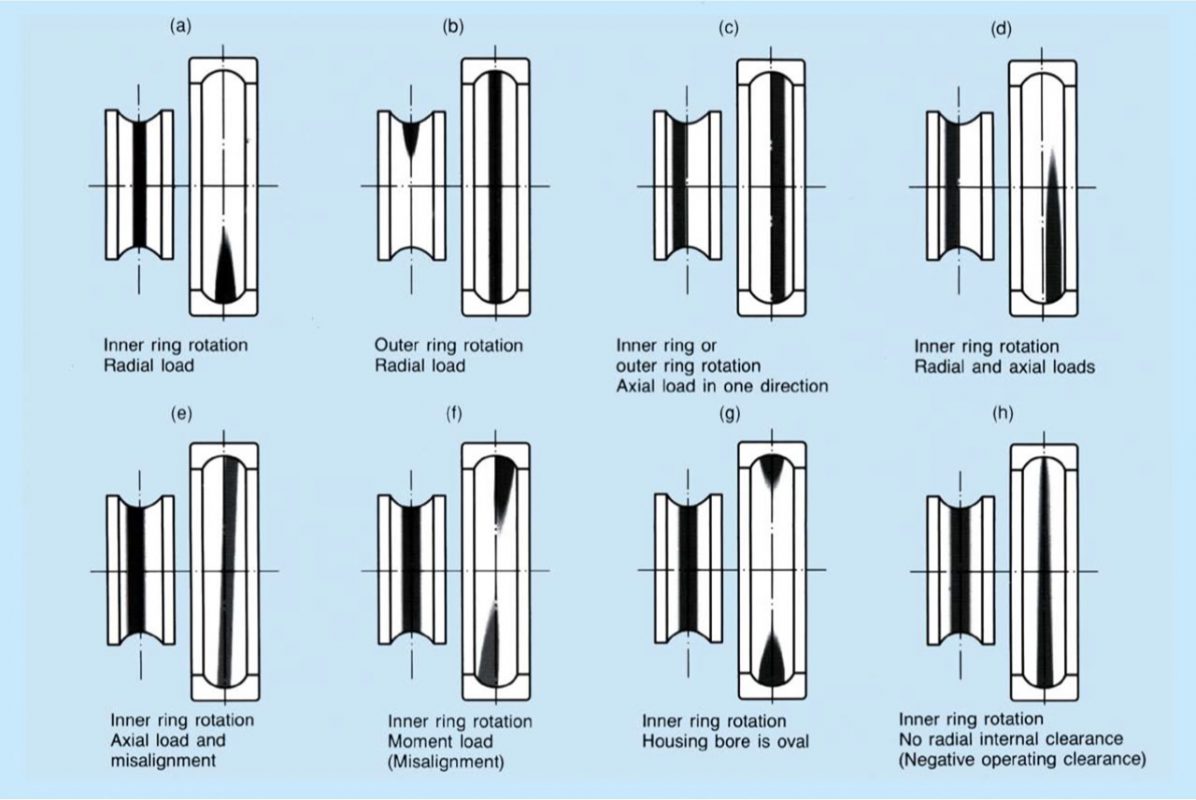

Typical running traces of deep groove ball bearings

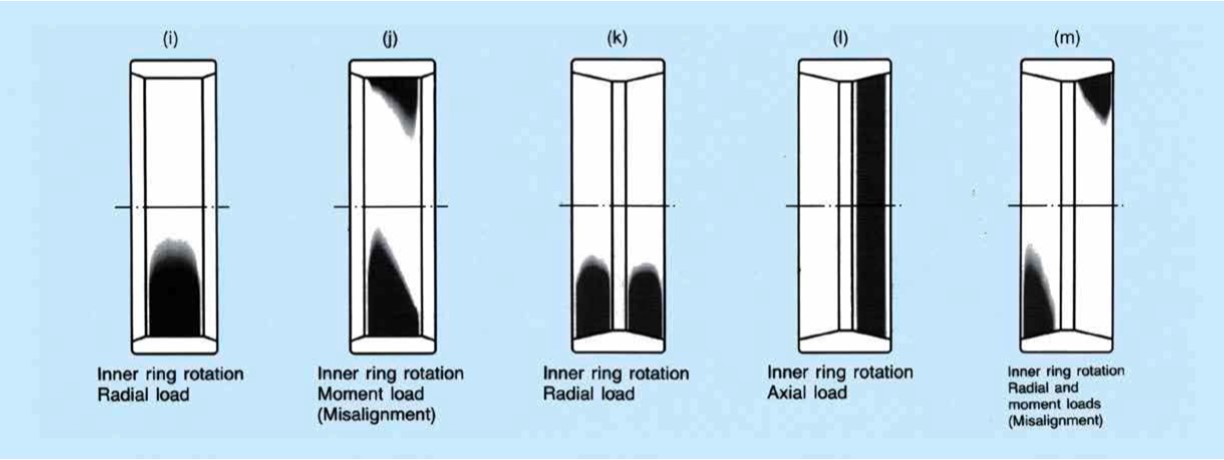

Typical running traces on roller bearings