High Performance NSK Bearings Adopted in New N700S Shinkansen Bullet Train

NSK technology contributes to world-top-class safety, stability, comfort, and environmental performance.

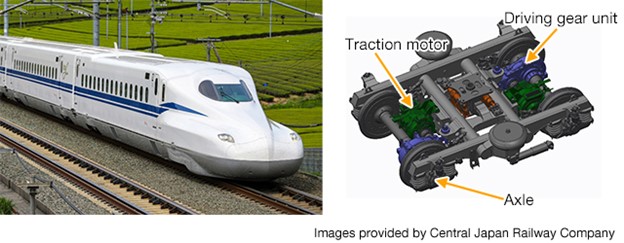

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President & CEO: Toshihiro Uchiyama) today announced that its high performance and high functionality bearings have been adopted in the newly developed N700S shinkansen bullet train, which entered service on July 1st, 2020, on the Tokaido Shinkansen Line between Tokyo and Osaka.

The N700S marks the start of a new era, being the first completely new shinkansen design from the Central Japan Railway Company in 13 years. The new design delivers the ultimate in safety, stability, comfort, and environmental performance.

NSK bearings have been adopted in the driving gear unit (gearbox), axle, and traction motor for their ability to enhance the key areas of safety, stability, comfort, and environmental performance (reducing environmental impact).

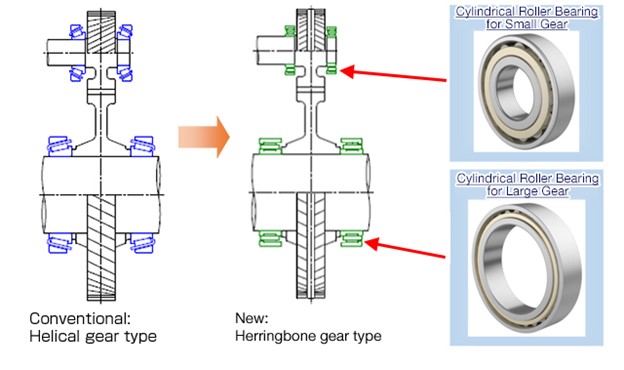

1) Driving gear unit bearings

The N700S is the first shinkansen to adopt herringbone gears, which offer increased reliability and lower noise. Driving gear unit bearings are subject to intense shocks and vibrations, so extending bearing life under these severe conditions is a top priority. NSK has been supplying tapered roller bearings for helical gears in shinkansen for decades. Drawing on this experience, NSK specially designed a flanged cylindrical roller bearing that delivers longer life, lower heat generation, and reduces maintenance requirements compared to previous models.

Highlights

- Improved seizure resistance by optimizing the design of areas that do not contact the flange face.

- Adopted high-strength machined-brass cage optimized with NSK’s R-pocket technology that reduces internal stress in the cage structure.

2)Axle bearings

NSK further improved on the design of its double-row tapered roller bearings used in the N700 and N700A to deliver even higher reliability and lower maintenance costs. The new design offers longer life, lower heat generation, and other enhancements.

3)Traction motor bearings

Cylindrical roller bearings and deep groove ball bearings with plasma-sprayed ceramic-coated outer rings prevent electrolytic corrosion. This prevents corrosion arising from electricity passing through the inside of the bearing, thereby increasing reliability.