How to install NSK Ball Screw and Support Units

Correct installation of NSK Ball Screw is important for long life, low friction and high accuracy. Find out how you can install the NSK Ball Screw, essential for linear motion, using proper procedure.

- Clean the mounting surface of support unit housing and base.

- Temporarily install the ball screw and support units housings

- Install support unit. Loosely install the lock nut.

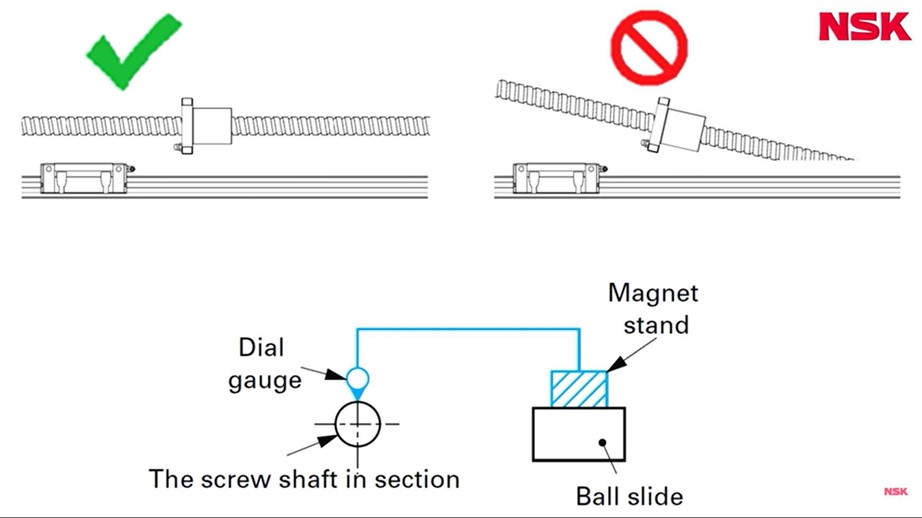

- Confirm vertical alignment of ball screw against linear guide

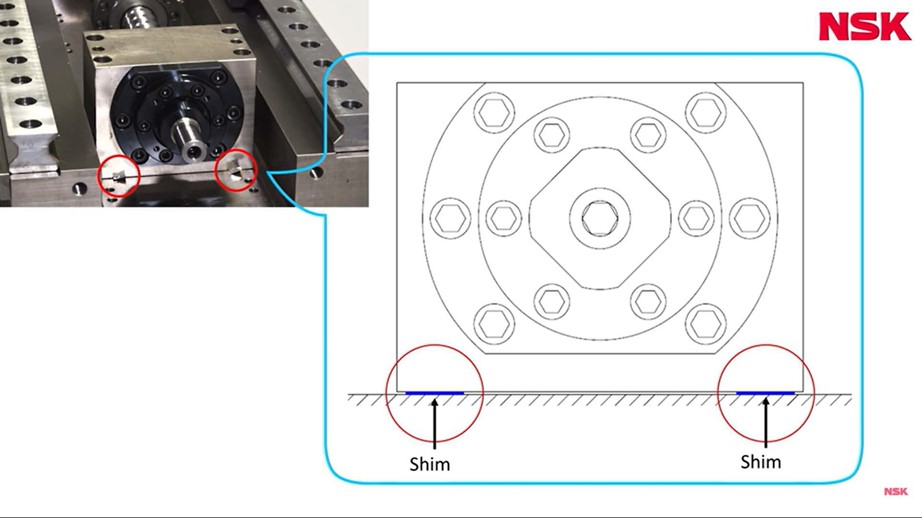

- Adjust the position of support unit housing to maintain parallelism (vertical) using shim etc.

- Confirm lateral alignment of ball screw against linear guide

- Adjust the position of support unit housing to maintain parallelism (horizontal)

- Tighten bolts with specified torque to fix support unit housing

- Check shaft end runout while locknut is loosely tightened.

- While adjusting the shaft end runout, fasten the locknut to attain required tightening torque

- Re-attach the moving table

- Attach nut housing to moving table

- If you are using long length ball screw, move the ball screw nut toward the support unit in order to minimize the bending of screw shaft by self-weight of the nut

- Attach ball screw´s nut to nut housing

- Loosen the bolts that fasten the table to the nut housing, and re-fasten them

- Loosen the bolts that fasten the nut housing and the nut, and re-fasten them

- Tighten bolts with specified torque

- Measure the driving torque of ball screw with the moving table in the center

- Measure the driving torque of ball screw with the moving table at right stroke end

- Measure the driving torque of ball screw with the moving table at left stroke end

- If the ball screw drive torque is excessive or has variation, or if the motion is not smooth, then there may be misalignment problem. Try to re-install the ball screw.

- Attach motor bracket to base

- Measure inclination of motor mounting surface against ball screw. If inclination is large, adjust with shim etc.

- Measure eccentricity of motor mounting pilot bore against ball screw. If eccentric error is large, adjust the position of motor bracket.

- Check coupling´s specification for allowable inclination and eccentricity error.

- Attach coupling and motor. Affix motor with bolts.

- Check that coupling can rotate freely before tightening the screw.

- Tighten bolts of the coupling, to connect shaft end with the motor shaft.

- Refer to catalog for recommended tightening torque of cap screw and locknut, mounting accuracy requirements.

Upload Image...